Getting to the Best Results Each Time

Cox pursues an operations strategy that deploys technology, processes and methods for optimal outcomes. Our approach inspires communication, teamwork and collaboration. Together, we achieve greater efficiency, mitigate risk and improve safety to deliver predictable results for you.

Preconstruction Services

The Better the Start, the Stronger the Finish

The sooner we engage with you, the better we can help enable the best project outcomes. We’re ready to partner across your relationships and project teams from the time you start conceptualizing a project. We use our decades of HVAC insight to contribute to optimal approaches to reaching your goals. Not only are there few challenges we haven’t addressed in the category, but we bring the latest thinking and technologies to bear through our firmwide dedication to continuous improvement. We’re ready to help you with:

Conceptual Estimating Budget Support

- Scenario/option planning: We explore and identify optimal routes to your goals

- Manpower loaded pull planning/scheduling: Know that you’ve got the right resources at every stage

Design Assist

- Target Value Design

- Validated Target Cost

- Extensive experience informed by years of “lessons learned” on complex healthcare, bio/pharm and commercial projects

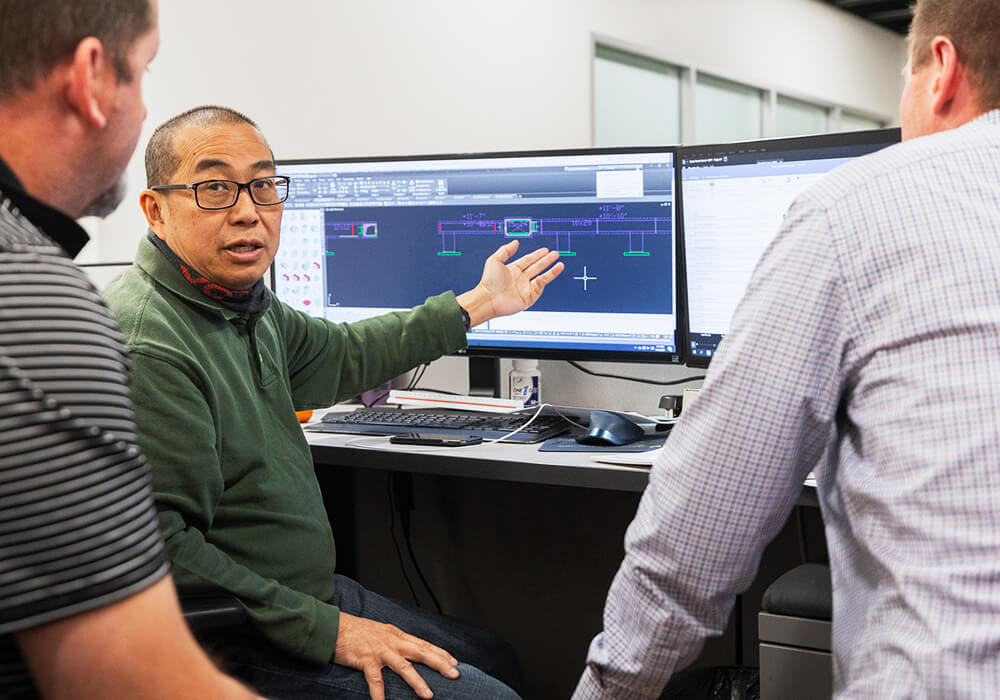

BIM

BIM is the brains of any building project. Utilizing the latest Autodesk software, our talented BIM specialists help you map the physical and functional dimensions of your space to optimize planning. We leverage Revit and Navisworks’ unified 3D modeling environment to seamlessly support virtual multi-trade coordination, significantly enhancing the prefabrication modular construction process.

Latest Tools

Our field personnel are also equipped with the latest tools, such as Trimble 3D Scanning Technology, Procore and Bluebeam.

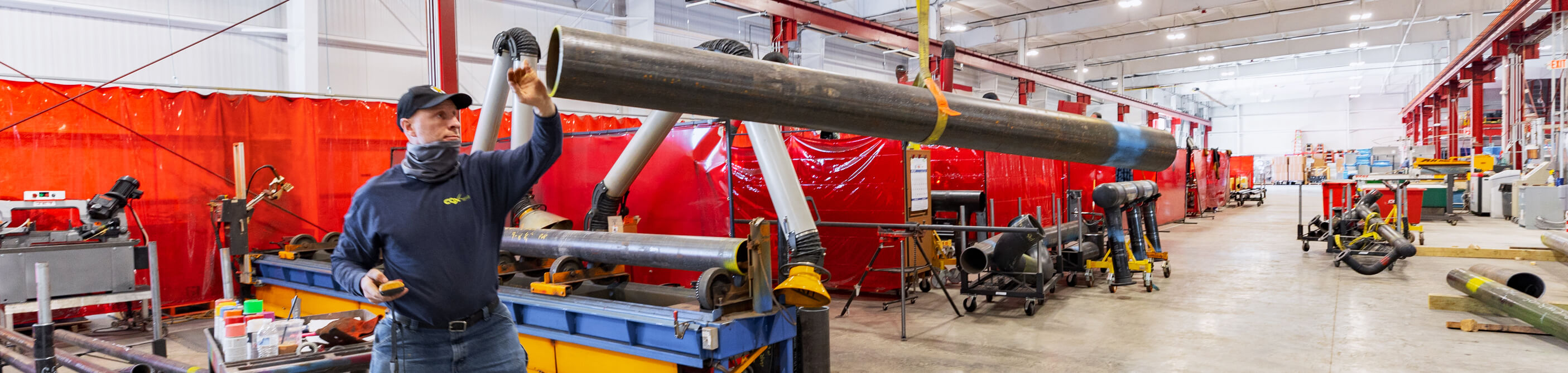

Fabrication

Sheet Metal, Pipe, Modular

We continually advance and enhance our capabilities to support yours. This ranges from the skills we instill in our workforce, to the spaces and infrastructure we use to create your HVAC solutions. For example, Cox has recently commissioned a new 40,000 sq ft Sheet Metal and Pipe Fabrication facility at our Randolph campus. The space houses capabilities and capacity including:

- 7,500 sq ft of swing space for Modular/Multi-trade fabrication opportunities. That means that we can scale up capacity to meet the needs of even the largest jobs.

- Innovative Lean fabrication methods to mitigate project schedule and safety risks while delivering cost effective solutions

- Sheet Metal Coil line/plasma cutting tables

- Multiple pipe weld stations, Victaulic stations and plasma cutting capability

Markets Served

Every client is unique, and we approach every relationship ready to apply our decades of expertise to your particular needs.

Regional Presence

Cox works with the most sophisticated construction managers and owners in the region across a range of markets

Scalability

Our projects range from $30M core and shell laboratories to $10K office Tenant Interior (TI) fit-outs

Essential Industries

Cox plays a major role performing mission critical, turn-key life cycle equipment replacement at major healthcare and life science facilities

Range

Through synergy with our sister companies Cambridgeport Custom and Cambridgeport Air Systems, we can meet myriad needs from one consolidated source